In most plants, the gas detectors on the field have evolved faster than the control panel in the control room. Smart transmitters are talking in 4–20 mA, relays, Modbus… but the panel is often still a basic annunciator, with limited diagnostics and almost no flexibility.

GasGuard M16 has been designed to close that gap.

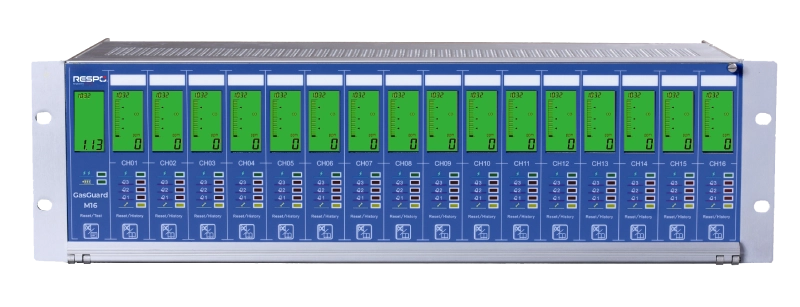

It’s a SIL2-approved, modular gas detection control panel that lets you start small and scale up to 16 channels in a single 3U, 19” rack – without compromising on safety or ease of operation. GasGuard M16

Modular by design, scalable by choice

Every site is different. Some need just a few detectors; others need dozens spread across multiple process units. GasGuard M16 uses independent channel cards so you can:

- Start from 1 channel and expand up to 16 channels per rack

- Mix and match oxygen, toxic and flammable gas detectors (2-wire or 3-wire)

- Use industry-standard 4–20 mA inputs (sink or source) and analogue 4–20 mA / 1–5 V outputs for DCS/PLC integration

If your site grows or processes change, you simply add more channel cards – not a whole new panel.

Clear information, quicker decisions

When an alarm comes, operators don’t have time to decode complex menus.

GasGuard M16 keeps things visual and intuitive:

- A rolling LCD display shows which channel is active

- Each channel has its own bar-graph display scaled from 0 to full range, so you can “see” gas build-up instantly

- Per-channel LEDs show alarm, fault and inhibit states at a glance

- Common alarm LEDs on the main display card let you check the overall rack status in a second

Daily operations – acknowledging alarms, resetting channels, checking readings – are all done from front-panel push buttons. No laptop needed.

Built for safety, not just compliance

In critical applications, the panel itself is a safety layer. GasGuard M16 has been engineered with that philosophy:

- Three gas alarm levels per channel (Alarm 1, 2 and 3) plus Fault and Over-range

- Independent and common relays for each level, with configurable voting logic

- 85 dB internal audible alarm, plus dedicated outputs for external audio/visual devices

- Main and standby power overload and short-circuit protection

- Optional battery backup to keep monitoring alive during power disruptions

The result is a panel that not only meets safety standards but supports real-world emergency response.

Ready for onshore, offshore and everything in between

Whether your installation is a refinery, LNG terminal, CGD station or chemical plant, GasGuard M16 is built to handle demanding environments:

- 19” rack-mount (3U) or wall-mount versions

- Rugged aluminium alloy enclosure, <10 kg

- Wide operating window: –20 °C to +55 °C, 0–95% RH (non-condensing)

- AC mains (100–260 VAC) or 24 VDC supply options

For integration, the panel offers RS-485 (Modbus RTU) communication, enabling connection to SCADA, DCS or remote monitoring systems.

Designed for modern gas detection architectures

A few ways customers are using GasGuard M16:

- Upgrading legacy gas panels while retaining existing field detectors

- Centralising multiple skid-mounted detectors into one SIL2-rated system

- Combining toxic, oxygen and flammable monitoring in a single rack

- Providing a compact, high-density solution for analyser shelters and control rooms

Wherever continuous gas monitoring is critical, GasGuard M16 becomes the decision-making heart of the system.

Let’s talk about your next upgrade.

If you’re planning to expand your gas detection network, replace an ageing panel, or move towards a SIL-compliant architecture, GasGuard M16 offers a practical, modular path forward.

📩 Feel free to reach out or comment if you’d like to explore how this platform can fit into your existing or upcoming projects.