Causes of Blind Spots

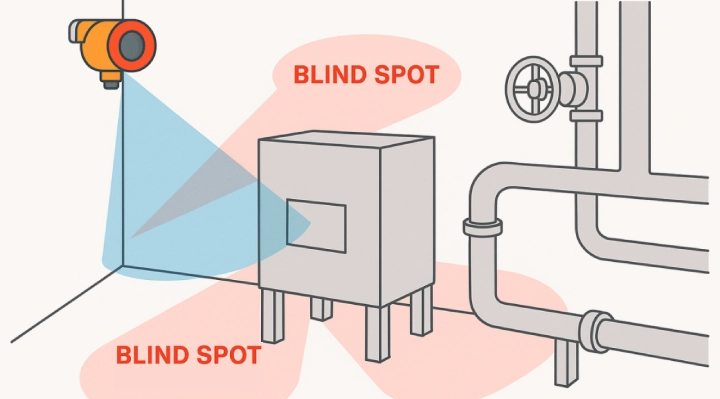

- Obstructions: Equipment, walls, piping, or structures can block gas dispersion paths and prevent detectors from sampling the area properly.

- Detector Placement: Incorrect mounting height or position (too high, too low, or too far from potential leak sources) can create unmonitored pockets.

- Gas Behavior: Some gases are lighter or heavier than air. If detectors are not placed considering buoyancy (e.g., methane rises, propane sinks), leaks can accumulate outside the detector’s sensing zone.

- Coverage Angle: For detectors like flame or open-path IR, each unit has a finite field of view. Anything outside this angle is a blind spot.

Why Blind Spots Matter

- Gas may accumulate undetected in these areas, leading to unsafe conditions despite having a detection system installed.

- Regulators (like OISD, OSHA, IEC 60079 standards) and end-users often require coverage studies to ensure blind spots are minimized.

How to Minimize Blind Spots

- Perform a Fire & Gas Mapping Study using computational fluid dynamics (CFD) or dispersion modeling.

- Follow guidelines (e.g., OISD-STD-116, ISA TR84.00.07) to optimize placement.

- Use a combination of detectors (fixed point, open-path, ultrasonic, flame) for layered coverage.

- Conduct site surveys and periodic reviews when layouts or processes change.

👉 In simple words: A blind spot is an area where gas could leak but the fixed detector won’t catch it due to placement, obstacles, or gas behavior. #GasDetection #IndustrialSafety #ProcessSafety #WorkplaceSafety #PlantSafety #SafetyFirst